THE LONG WAY HERE 02 : Before we go anywhere

Before We Go Anywhere

Before a Rhythmus pack ever goes out for a ride, it spends a long time going nowhere at all.

The earliest prototypes of every Rhythmus product are built with my own two hands. This allows me to slow down, question the design, realize how stupid some of my ideas are, and rebuild. Long before production even crosses my mind, I spend hundreds of hours ideating, sketching, 3D modeling, patterning, sewing, fitting, and testing prototypes right here in Colorado.

This stage is about learning. It’s about trying something new and failing. It’s about figuring out what works eight hours or eight days into a ride.

From Idea to Reality-ish

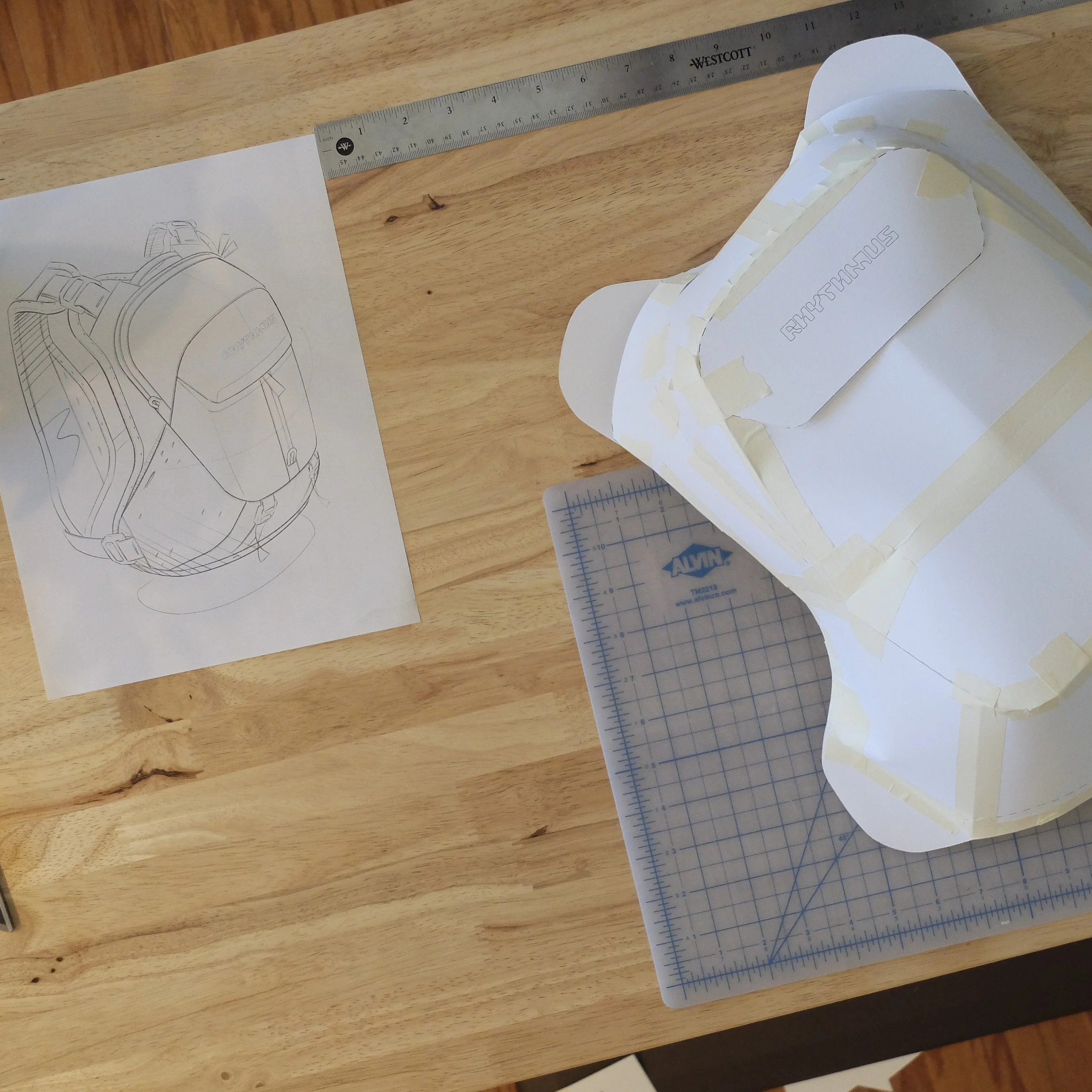

Every product starts as a sketch. For me, it is the fastest way to get an idea out of my head and into the real world. Even if it’s just a drawing. It’s a start, and it’s where an idea really starts to transform into something physical.

Once I’ve roughed out the general layout and seaming of a product, it moves into 3D. I create a wireframe on the computer, turn that into a flat pattern, then cut and assembled it into something three dimensional. The first version is always made from paper, and it’s rarely right. Sometimes the whole shape feels unbalanced. Sometimes a seam that felt so interesting in a sketch just doesn’t work in the real world. It ends up being a lot of 3D model, print, assemble, refine, repeat. This stage is about sculpting. It’s about refining an idea until it feels like what I envisioned in my head. Every once in a while, I’ll surprise myself by how quickly an idea seems to come together, but usually I’m sitting in my office making paper models for days before it finally feels right.

Sew, Ride, Repeat

After the paper sample is at a point where it feels right, I can finally move on to using some fabric. Early builds are usually pretty rough, but they are meant to show problems, not look pretty. Once a prototype exists, it gets worn. On short rides. On long rides. Loaded lightly and overloaded on purpose. Problems show up. Notes are taken. Stitch lines are adjusted. Panel shapes are redrawn. And a new version is made.

Most designs go through multiple in-house prototypes. Each one is a response to the last. I sew a new version, ride it, take it apart mentally and sometimes literally, then sew it again. This process can feel repetitive, but it allows me to identify problems early, and try to solve them before they get too baked into the product.

Making Moves

Eventually, the problems start to feel solved. The design stops changing dramatically, and redesign becomes refinement.

That is the point where the process moves overseas. Once the pattern, fit, and function are resolved in-house, the work continues in Vietnam. Final sampling, refinement for production, and the transition from prototype to final product all happen there. That part of the story is longer, slower, and built on the foundation laid with my own two hands right here in Colorado.

In the next part of this series, I’ll talk about what happens when an idea moves from my hands to the factory’s, and how designs are translated, refined, and ultimately built in Vietnam.

This is where a prototype becomes a product.